free shed plan

Thursday, November 21, 2024

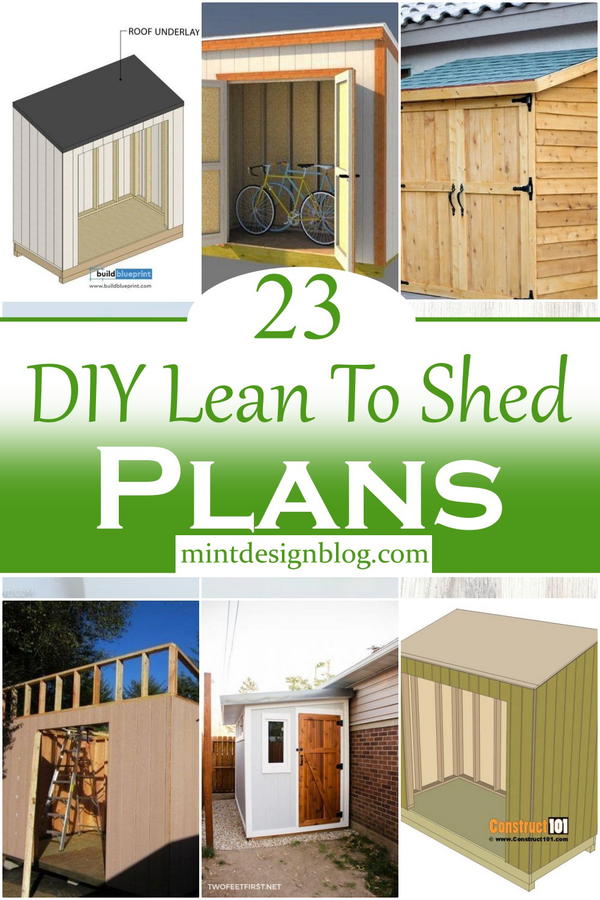

Reclaim Your Space: Building a Lean-To Shed the Easy Way

Reclaim Your Space: Building a Lean-To Shed the Easy Way

The desire for additional storage or workspace is a common challenge faced by homeowners. While constructing a fully enclosed shed can be a significant undertaking, a lean-to shed presents a more manageable and efficient solution. This guide provides a comprehensive overview of building a lean-to shed, emphasizing simplicity and practicality for the DIY enthusiast.

Planning and Design Considerations

Before commencing construction, meticulous planning is crucial to ensure a successful outcome. This phase involves several key steps, each contributing to the overall structural integrity and functionality of your lean-to shed.

Determining the Location and Size

The optimal location for your lean-to shed depends on several factors. Consider proximity to existing structures, access to utilities (if required), and the prevailing wind direction. Assess the available space and determine the desired dimensions of your shed. Remember to check local building codes and regulations before proceeding. Overly ambitious dimensions for a first-time builder are strongly discouraged; a smaller, simpler structure is a more achievable and less frustrating project.

Choosing the Right Materials

Material selection significantly impacts the durability, cost, and aesthetic appeal of your lean-to shed. Pressure-treated lumber is highly recommended for its resistance to rot and insect damage, especially for the foundation and framing. Consider using composite materials for decking or siding for low-maintenance appeal. For roofing, asphalt shingles are a popular and cost-effective choice, offering good protection against the elements. Explore different roofing options to find one that aligns with your budget and aesthetic preferences.

Consider these factors when choosing your materials:

- Budget: Establish a realistic budget and select materials accordingly. Pricing varies significantly between lumber grades and composite materials.

- Durability: Prioritize materials known for their resistance to weather damage, pests, and decay.

- Aesthetics: Choose materials that complement the existing structures on your property.

Obtaining Necessary Permits

Depending on your location and the size and complexity of your lean-to shed, you may be required to obtain building permits. Contact your local building department to inquire about permit requirements and submit the necessary applications well in advance of construction. Failure to obtain necessary permits can result in fines or even demolition orders.

Foundation and Framing

A solid foundation is paramount for a stable and long-lasting lean-to shed. The framing provides the structure's skeleton, supporting the roofing and walls. Careful execution of these steps is crucial for the overall success of the project.

Preparing the Foundation

A simple concrete slab or a compacted gravel base provides a suitable foundation for a lean-to shed. For a concrete slab, ensure the ground is level and properly compacted. For a gravel base, excavate to a suitable depth, add gravel, and compact thoroughly. The foundation's dimensions should match or slightly exceed the planned footprint of the shed.

Constructing the Frame

The frame of your lean-to shed will typically consist of pressure-treated lumber. Begin by constructing the base frame, ensuring squareness and levelness. Erect the vertical supports, ensuring they are plumb and properly braced. Install the roof rafters, ensuring they are properly spaced and securely attached to the vertical supports and the supporting wall of the existing structure. Use appropriate fasteners, such as galvanized nails or screws, to ensure strong connections.

Accuracy is paramount during framing. Use a level and square to ensure all components are properly aligned. Improper framing can compromise the structural integrity of the shed.

Roofing and Siding

Once the framing is complete, you can proceed with roofing and siding installation. These steps contribute to the shed's weather resistance and aesthetic appeal.

Installing the Roofing

The roofing process begins with installing underlayment, a waterproof membrane that protects the structure from moisture. Then, install your chosen roofing material, following the manufacturer's instructions carefully. Ensure proper overlapping of shingles or other roofing materials to prevent leaks. Secure all roofing materials with appropriate fasteners.

Proper ventilation is important to prevent moisture buildup. Consider installing ridge vents or other ventilation features.

Adding Siding

Siding protects the structure's interior from the elements and enhances its appearance. Choose your siding material and install it according to the manufacturer's instructions. Ensure proper alignment and overlapping of siding pieces. Seal any gaps or seams to prevent water infiltration.

Finishing Touches and Considerations

Once the primary construction is complete, several finishing touches can improve the functionality and aesthetics of your lean-to shed.

Adding a Door or Window

A door provides convenient access to the shed's interior. A window allows for natural light and ventilation. Select and install appropriate doors and windows, ensuring they are properly sealed to prevent drafts and leaks.

Interior Finishing

Interior finishing can include painting or staining the walls and floor, adding shelving, and installing lighting. These additions improve the shed's usability and aesthetic appeal.

Safety Precautions

Throughout the construction process, prioritize safety. Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection. Use caution when working with power tools and follow all manufacturer instructions. Ensure the work area is well-lit and free of obstructions.

Building a lean-to shed can be a rewarding and relatively straightforward project. By following these guidelines and exercising careful planning and execution, you can successfully create a valuable addition to your property, reclaiming valuable space and enhancing its functionality. Remember to always prioritize safety and adhere to local building codes and regulations throughout the construction process.

Build a Custom Pallet Shed with These Easy-to-Follow Plans

Build Your Own Custom Pallet Shed: A Step-by-Step Guide

Hey there, folks! So you're thinking about building a shed, huh? That's awesome! And even better, you're thinking about doing it with reclaimed pallets â€" super eco-friendly and often budget-friendly too! This guide will walk you through building your very own custom pallet shed. Don't worry, it's not as daunting as it sounds. We'll break it down into manageable steps, and even if you're a total newbie to DIY, you can totally pull this off. Let's get started!Planning and Preparation: The Foundation of a Great Shed

Before you even think about touching a single pallet, some planning is essential. This stage will save you headaches (and maybe some materials) down the line.Choosing Your Palettes

This is crucial. Not all pallets are created equal! You need to source sturdy pallets that are in good condition. Look for pallets made of heat-treated wood (HT) â€" you'll find this stamped on them â€" as it's safer and less likely to have pests or harmful chemicals. Avoid pallets that are heavily damaged, rotting, or show signs of significant insect infestation. Consider the size and number of pallets you'll need based on your desired shed dimensions. Visiting local businesses (like grocery stores or lumber yards) and asking if they have any to spare is a great way to get free or cheap pallets.Designing Your Shed: Size and Style

Sketch out a basic design. How big do you want your shed? How much stuff do you need to store? Think about the door placement, roof style (a simple gable roof is easiest for beginners), and any windows you might want. A simple rectangular shed is the easiest to construct. Remember, this is a pallet shed, so keep the design relatively straightforward. Don't overthink it â€" simple is often best!Gathering Your Tools and Materials

Beyond pallets, you'll need a few things:- Measuring tape

- Level

- Hammer or nail gun (a nail gun is a huge time saver!)

- Screws (long, heavy-duty exterior screws are recommended)

- Wood glue (exterior grade)

- Safety glasses

- Work gloves

- Saw (circular saw or hand saw)

- Post hole digger (if you're creating a more permanent foundation)

- Concrete (optional, for a more permanent foundation)

- Roofing felt or other roofing material

Building the Frame: The Shed's Skeleton

Now for the fun part! We'll start by constructing the frame of your shed.Creating the Base

Lay down your chosen base â€" either directly on the ground, on compacted gravel, or even on a small concrete slab for a more permanent structure. Arrange your pallets to form the desired base dimensions. Ensure they are level and secure. You can use screws or longer nails to fasten the pallets together.Building the Walls

This is where you’ll use the remaining pallets to construct the walls. Remember to measure carefully before attaching the pallets. You might need to cut some pallets to fit perfectly. Use a combination of screws and wood glue for added strength. For a more structurally sound shed, consider adding vertical support beams (2x4s or similar) between the pallets to brace the walls.Constructing the Roof

For a gable roof, you'll create two triangular sections. Use more pallets (possibly cut to size) to form the roof rafters, making sure they are securely attached to the top of the walls. Then, cover your roof with roofing felt and your chosen roofing material. Shingles, corrugated metal, or even heavy-duty plastic sheeting can work.Finishing Touches: Making Your Shed Shine

Once the main structure is complete, it's time to add the finishing touches.Adding a Door

You can either use a pre-made door or create one using more pallets. If making your own, ensure it's properly reinforced and securely hung. Consider adding hinges and a latch for security.Adding Windows (Optional)

If you’d like windows, you can cut openings in your pallet walls and install some small windows. You can get inexpensive windows from a hardware store or even repurpose existing windows.Sealing and Painting (Optional)

To protect your shed from the elements and enhance its appearance, consider applying a sealant or weatherproofing treatment. You can also paint your shed to match your existing aesthetic.Safety First!

Remember safety first! Always wear safety glasses and gloves when working with tools and materials. Be mindful of lifting heavy pallets â€" get help if needed. If you're unsure about any step, don't hesitate to consult with a more experienced DIY enthusiast or professional.

Commonly Asked Questions

Q: How long does it take to build a pallet shed?

A: This depends on the size and complexity of your shed, your DIY skills, and how many people are helping. A simple shed can take a weekend, while a more complex one might take several days or even longer.

Q: How much does it cost to build a pallet shed?

A: The primary cost is the materials beyond the pallets themselves. If you find free pallets, your cost could be surprisingly low. Otherwise, expect to spend between $100 and $500 on additional materials, depending on size and complexity.

Q: Are pallet sheds durable?

A: With proper construction and sealing, a pallet shed can be surprisingly durable. However, it's not as weather-resistant as a shed made from treated lumber. Regular maintenance is recommended.

Q: What kind of permits do I need?

A: Permitting requirements vary by location. Check with your local authorities before starting construction to ensure you comply with all regulations.

Q: Can I use any type of pallet?

A: No, use only heat-treated (HT) pallets. Other pallets may contain harmful chemicals or pests.

And there you have it! Building a pallet shed is a rewarding project that combines creativity, resourcefulness, and a whole lot of satisfaction. Remember to take your time, plan well, and enjoy the process! Happy building!Wednesday, November 20, 2024

DIY Lean-To Shed Build: Tips for Efficient and Affordable Construction

DIY Lean-To Shed Build: Tips for Efficient and Affordable Construction

Building your own lean-to shed offers a rewarding blend of practicality and cost savings. This simple structure provides valuable storage space while allowing you to hone your DIY skills. This guide provides a step-by-step approach to constructing an efficient and affordable lean-to, minimizing waste and maximizing your budget.

Planning Your Lean-To Shed

Before you even touch a tool, meticulous planning prevents costly mistakes down the line. Start by determining your shed's purpose. Will it house gardening equipment, bicycles, or simply overflow storage? This dictates the required size. Consider local building codes and regulations â€" you might need permits depending on size and location. Sketch your design, noting precise dimensions for the roof, walls, and base. Accurate measurements are crucial for material purchasing and efficient construction.

Choosing the Right Location

Select a level, stable area for your lean-to. Consider proximity to power sources if you plan on adding electricity. Ensure the location allows for easy access and doesn't obstruct walkways or other structures. Proper drainage is also key; avoid low-lying areas prone to water accumulation.

Material Selection: Balancing Cost and Quality

Prioritize durability and affordability when choosing materials. Pressure-treated lumber resists rot and insects, making it an excellent choice for the base and framing. For the roofing, consider inexpensive yet durable options like corrugated metal or asphalt shingles. Source materials from local suppliers to minimize transportation costs. Compare prices from different suppliers to find the best deals.

Construction: A Step-by-Step Guide

With your plan finalized and materials gathered, construction begins. Start by preparing the base. Level the ground and create a foundation using concrete blocks, gravel, or a simple wooden base, depending on your chosen method and budget. This provides stability and prevents rot. Next, erect the frame, ensuring all angles are square and plumb. Use appropriate fasteners like screws or nails, reinforcing critical joints with metal brackets.

Framing and Roofing

The frame forms the skeleton of your shed. Construct the walls using the chosen lumber, ensuring they're firmly attached to the base. For the roof, install rafters, ensuring adequate slope for water runoff. Sheathe the roof with plywood or OSB board before applying your chosen roofing material. Remember to secure all elements to withstand weather conditions. Carefully follow the manufacturer's instructions for installing roofing materials.

Finishing Touches

Once the roof is complete, add any desired finishing touches. Consider adding a door for easy access. If you desire, paint or stain the exterior to protect the wood and enhance aesthetics. Installing simple shelving can dramatically improve storage organization. Consider adding ventilation to prevent moisture build-up.

Tips for Efficiency and Cost Savings

Maximize efficiency by organizing your tools and materials beforehand. Having everything readily available minimizes wasted time. Consider using recycled or reclaimed materials where possible, such as salvaged lumber for framing. Enlist help from friends or family to accelerate the construction process. Proper planning and execution minimizes material waste, contributing significantly to cost savings. Don't hesitate to seek guidance from experienced DIYers or watch helpful online tutorials.

Building a lean-to shed is a rewarding project that combines practicality and cost-effectiveness. By following these tips and paying close attention to detail, you can construct a durable, affordable structure that enhances your property and provides valuable storage space for years to come.

Saturday, November 16, 2024

12x20 Shed Loft Plans: Perfect for Hobbyists and Gardeners

12x20 Shed Loft Plans: Perfect for Hobbyists and Gardeners

So, you're dreaming of a bigger, better shed? One that's not just for storing gardening tools and lawnmowers, but a real workspace, a haven for your hobbies, maybe even a little quiet retreat? A 12x20 shed with a loft is the answer! It offers a surprisingly spacious footprint, and that added loft space unlocks a whole new world of possibilities. Let's dive into why a 12x20 shed with a loft is a fantastic investment and how you can make your dreams a reality.

Why Choose a 12x20 Shed with a Loft?

A 12x20 shed isn't just a bigger box; it's a versatile space waiting to be customized. The extra square footage is amazing, but the loft really takes it to the next level. Think about it: you get double the storage, double the potential!

Ample Storage: The Obvious Advantage

Let's face it, we all accumulate stuff. Garden tools, potting supplies, holiday decorations, sports equipment â€" the list goes on and on. A 12x20 shed gives you the room to organize it all, and the loft allows for even more storage. Imagine neatly stacking away seasonal items, keeping your frequently used tools easily accessible downstairs, and having a dedicated space for everything else.

Dedicated Hobby Space: Unleash Your Creativity

Got a passion for woodworking, painting, sewing, or something else entirely? That 12x20 shed with a loft can become your dedicated creative sanctuary. The loft can serve as a studio, a workshop, or a quiet space to concentrate on your projects. No more cramming your hobbies into a cluttered corner of the garage!

Guest Room or Retreat: Unexpected Versatility

While not a full-fledged guest house, a well-insulated and finished 12x20 shed with a loft can make a surprisingly comfortable guest room for overnight visitors. Or, even better, it could be your personal escape â€" a quiet reading nook, a meditation space, or a place to simply unwind and relax.

Planning Your 12x20 Shed Loft: Key Considerations

Before you grab your hammer and nails (or your blueprints and software!), there are a few crucial points to consider.

Local Building Codes and Permits: Do Your Homework

This is paramount. Contact your local building department to check on regulations for shed construction, including size limitations, foundation requirements, and necessary permits. Failing to obtain the proper permits can lead to hefty fines and even demolition orders. Believe me, it's worth the time and effort to get it right from the start.

Foundation: Stability is Key

Your shed’s foundation is crucial for long-term stability. Consider options like a concrete slab, concrete piers, or a pressure-treated lumber base. The choice will depend on your budget, soil conditions, and local building codes. A sturdy foundation will prevent settling and protect your investment.

Loft Access: Safety and Convenience

Think carefully about how you’ll access the loft. A sturdy staircase is ideal, but a pull-down ladder can be a space-saving alternative. Consider the height of the loft ceiling and ensure the access point is safe and convenient.

Insulation and Climate Control: Year-Round Use

If you plan to use the shed year-round, proper insulation is a must. This will keep the interior comfortable, regardless of the weather. Consider adding insulation to the walls, roof, and floor. You might even think about adding a small heater or air conditioner, depending on your needs.

Designing Your Dream Space: Maximizing Functionality

This is where the fun really begins! Think about how you'll use your 12x20 shed and design the space accordingly.

Workbenches and Storage Solutions: Optimize Your Workspace

If you're using the shed as a workshop, invest in sturdy workbenches and plenty of storage solutions. Think about built-in shelving, cabinets, and pegboards to keep everything organized and accessible.

Electrical Wiring and Lighting: Powering Up Your Shed

Adding electricity is a great way to enhance the functionality of your shed. You'll need to hire a qualified electrician to ensure it's done safely and correctly. Proper lighting is essential for comfortable working conditions.

Ventilation: Maintaining a Healthy Environment

Proper ventilation is important, especially if you're using the shed for activities that generate dust or fumes. Install windows and vents to ensure good airflow and prevent the buildup of moisture.

Finishing Touches: Personalizing Your Space

Once the structure is complete, you can personalize your shed with paint, flooring, and other finishing touches. Choose materials that are durable and easy to maintain.

Building Your Shed: DIY or Professional?

The decision to build your shed yourself or hire a professional is a personal one. Building it yourself can be a rewarding experience, but it requires time, skills, and tools. Hiring a professional will save you time and effort, but it will come at a higher cost. Weigh the pros and cons carefully before making your decision.

Frequently Asked Questions

Here are some common questions people have about 12x20 shed loft plans:

Q: How much does a 12x20 shed with a loft cost?

A: The cost varies widely depending on materials, finishes, and whether you build it yourself or hire a contractor. You can expect to spend anywhere from a few thousand dollars to well over $10,000.

Q: Do I need a permit to build a 12x20 shed?

A: Yes, almost certainly. Check with your local building department. Permit requirements vary by location.

Q: How much space will I have in the loft?

A: The usable loft space will depend on the height of the ceiling and the design of the loft itself. You'll likely have several hundred square feet of additional storage or work space.

Q: What kind of materials should I use?

A: The best materials are durable, weather-resistant, and meet local building codes. Pressure-treated lumber for the frame, metal roofing for durability, and exterior-grade plywood or siding for the walls are good starting points.

Q: Can I add electricity to my shed?

A: Yes, but you must hire a qualified electrician to ensure it's done safely and to code. Improper electrical work is dangerous.

Building a 12x20 shed with a loft is a big undertaking, but the rewards are immense. With careful planning, thoughtful design, and a little elbow grease (or a skilled contractor!), you can create a versatile and functional space that enhances your lifestyle for years to come. So, start dreaming, start planning, and get ready to build your dream shed!

Monday, November 11, 2024

How to Make a Pole Barn with a High-Security Design

Alright, so you want to build a pole barn, but not just any old pole barn. You want a fortress, a security vault disguised as a barn. I get it, you want to keep your valuables safe and sound, and you want to make sure that no one, and I mean no one, gets in without your permission. Let's talk about how to make your pole barn a high-security masterpiece.

Start with the Foundation: A Solid Base for Security

First things first, let's get that foundation right. A strong foundation is like the bedrock of your security. Don't skimp on this part. Forget those standard concrete piers, we're talking about something serious.

Reinforced Concrete: Imagine those piers, but beefed up with rebar. Think of it as adding extra muscle to your foundation.

Deep Foundations: Instead of just a few feet down, go deeper. You want your foundation to be anchored firmly, like a ship riding out a storm.

Perimeter Security: Think about burying a security fence around the perimeter of your foundation. This adds another layer of protection right from the ground up.

The Poles: More Than Just Support

The poles are the backbone of your pole barn, so you want them to be strong and durable. We're not talking about your average lumberyard poles here. We're talking about a higher level of strength.

Heavy Duty Steel: Forget wood. You need steel poles that can withstand the weight of a bear, not just a few bags of hay.

Thick Gauge Steel: The thicker the gauge, the tougher the pole. You want a pole that can stand up to any pressure.

Corrosion Resistant Coating: You want these poles to last, so choose a steel that's protected against rust and corrosion.

Walls: A Fortress of Protection

Now let's talk about the walls. You want them to be more than just sheet metal. You want them to be the ultimate deterrent.

Thick Gauge Metal Siding: Again, we're talking about serious metal here, not some flimsy stuff. Think of the metal used in bank vaults.

Double-Walled Construction: Two layers of metal are better than one. It makes it much harder for someone to break in.

Impact Resistant Panels: Imagine a wall that can withstand the force of a battering ram. That's what we're aiming for here.

Reinforced Door Frames: Don't forget the doorways! They need to be just as strong as the rest of the walls. Consider steel door frames with additional reinforcement.

The Roof: A Shield Against the Elements

The roof isn't just about keeping the rain out. It's another line of defense.

Heavy Duty Metal Roofing: You want a roof that can withstand high winds and even hailstorms.

Reinforced Ridge and Eaves: These are the weak points of a roof, so they need to be strong and secure. Consider using metal bracing or heavy-duty corner brackets.

Security Roof Hatch: You might need access to the roof for repairs or inspections, but you want to control that access. A security hatch, with a lock, is a good idea.

Doors: The Gatekeepers to Your Fortress

The doors are the entry point, so they need to be rock solid. Don't skimp on these.

Security Doors: Forget those standard barn doors. We're talking about heavy-duty steel doors with multiple locks and reinforced hinges.

Electronic Locks: Add electronic locks that require a code or a fingerprint scan for entry. Consider a keypad lock for easy access.

Video Surveillance: Cameras on the doors can deter would-be thieves and provide evidence in case of a break-in.

Lighting and Alarms: The Eyes and Ears of Your Barn

You want to deter potential thieves and give yourself peace of mind, so invest in a good security system.

Motion Sensor Lighting: Floodlights activated by motion can scare off intruders and provide a clear view of the area.

Perimeter Alarms: Sensors around the perimeter can alert you to any trespassers.

Interior Alarms: Motion sensors, door alarms, and window alarms can alert you to any activity inside your barn.

Remote Monitoring: Consider a system that allows you to monitor your barn remotely from your phone or computer.

Beyond the Basics: Additional Security Measures

You've got the foundation, the walls, the roof, the doors, and the security system. But you can take it a step further.

Concealed Security Cameras: These cameras can be hidden in plain sight, making it harder for intruders to spot them.

Security Lighting: Install floodlights around the perimeter of your property that illuminate the area in case of intrusion.

Motion-Activated Sprinkler System: A well-placed sprinkler system can be a big deterrent to unwanted visitors.

Fencing: A secure fence around the perimeter of your property can prevent unauthorized access and deter potential thieves.

Dogs: A dog can be a valuable addition to your security system. Choose a breed that is known for its protective instincts.

The Last Line of Defense: Planning and Vigilance

Even with a high-security pole barn, it's important to remember that no system is perfect.

Security Audits: Regularly review your security system to make sure it's up to date and functioning properly.

Neighbors and Security Teams: Establish relationships with your neighbors and let them know about your security measures.

Stay Vigilant: Be aware of your surroundings and trust your instincts. Report any suspicious activity to the authorities.

Building a high-security pole barn takes time and effort, but it's an investment worth making. Remember, you want your barn to be a safe haven for your belongings and a symbol of your peace of mind.

DIY Guide to Building a Pole Barn with Custom Doors and Windows

Okay, you've got the land, the vision, and the itch to build. A pole barn, huh? Solid choice. You're in for a rewarding project, and let me tell you, there's nothing quite like the satisfaction of building something with your own two hands (and maybe a few power tools). We're going to dive deep into building your pole barn, but with a twist â€" we're going to add some custom flair with unique doors and windows.

Getting Started: Blueprint and Materials

First things first, we need a solid plan. Grab a pen and paper (or fire up your favorite design software) and start sketching out your pole barn's dimensions. Consider the purpose, size, and features you want. Got a workshop in mind? Need storage space for your truck? Think about the layout and how you'll use the space.

Once you've got a good blueprint, it's time to get your materials list in order. Here's a breakdown of the key players:

Posts: Think sturdy, long-lasting, and pressure-treated to resist rot. Your trusty lumberyard will have plenty of options â€" choose the size based on the load your barn will carry.

Skids/Footings: A solid base is crucial for stability. Concrete footings offer a permanent solution, while skids provide a more flexible setup. Decide what works best for your location and project needs.

Framing Lumber: This is the backbone of your walls and roof. Choose sturdy 2x4s or 2x6s for reliable strength.

Roofing: Go for a sturdy, weather-resistant material â€" metal roofing is a popular choice for its durability and low maintenance. Don't forget about insulation!

Siding: Choose a style that complements your vision â€" from classic wood to modern metal, the possibilities are endless!

Doors and Windows: This is where the custom fun begins! We'll talk more about this later.

Setting the Stage: Foundations and Posts

Alright, time to get your hands dirty! First, we need to set those sturdy posts in place. If you opted for concrete footings, dig holes according to your blueprint and pour the concrete. Allow plenty of time for the concrete to cure before moving on. If you're going with skids, ensure they're level and secure for a solid foundation.

Now, it's time to erect those posts. Use a level to make sure everything is plumb and straight. You might need a couple of helping hands for this step. Once they're firmly set, brace them for extra support.

Building the Walls: Framework and Sheathing

With the posts standing tall, we can start framing the walls. Attach your chosen framing lumber to the posts, making sure to measure carefully and ensure the walls are square. Remember, a well-constructed frame is key to a strong and durable barn.

Now, let's add some sheathing to the walls. This layer of plywood or OSB (oriented strand board) adds rigidity and creates a smooth surface for the siding. Use nails or screws to secure the sheathing to the framing, ensuring it's flush and even.

Roofing the Beast: Truss, Sheathing, and Cover

Time to put a roof over your head (or your barn, rather). For most pole barns, pre-engineered trusses provide a simple and strong solution. Follow the manufacturer's instructions for installation, ensuring they're properly spaced and secured to the posts.

Once the trusses are up, add sheathing to the roof just like you did with the walls. Now it's time for the roofing material â€" choose your favorite and get to work! Remember, proper installation is key, so consult manufacturer instructions and maybe even call in a roofing pro if you're feeling unsure.

The Grand Finale: Siding and Finishing Touches

With the roof on, it's time to give your barn its personality. This is where you'll bring your siding vision to life. Whether it's classic wood, sleek metal, or a mix of both, choose your materials and follow the manufacturer's installation instructions.

Custom Doors and Windows: Your Personal Touch

Now, for the highlight â€" the custom doors and windows! Here's where your creativity can truly shine.

Doors: Imagine a massive sliding door that welcomes you to your workshop, or a pair of rustic barn doors adding charm to your storage space. Think about how you'll access the barn and what kind of style complements your overall design.

Windows: Let in the natural light with custom windows. Consider placement for optimal sunlight in your workshop or to showcase your stunning views. Maybe even add some stained-glass accents for a touch of artistry!

Don't Forget the Details:

Hardware: Strong hinges, sturdy handles, and stylish door hardware will add functionality and character to your barn.

Paint and Stain: Add a splash of color or a natural wood finish to complete the look. Choose colors and finishes that complement your overall design and reflect your personal style.

Building Your Dream: One Step at a Time

Building a pole barn with custom doors and windows is a fulfilling journey. It takes time, effort, and a little bit of know-how. But don't be intimidated â€" with proper planning, careful execution, and maybe a helping hand from a friend, you can achieve your vision and build the pole barn of your dreams.

Ready to Get Started?

I hope this guide has inspired you to embark on your own pole barn project. Remember, this is just a starting point â€" research, plan, and personalize to create a space that reflects your unique needs and style. Have fun building!

DIY Pole Barn Plans: How to Plan for Multiple Use Purposes

So you're thinking about building a pole barn. Good for you! They're incredibly versatile, affordable, and can be built relatively quickly. But before you start digging, let's talk about planning.

The key to a successful pole barn project is planning for multiple use purposes. After all, why settle for just a workshop when you could have a workshop and a weekend getaway?

Step 1: Dream Big (and Realistic!)

Think about what you envision using your pole barn for. Do you need space for your woodworking projects, maybe a spot to park your vehicles, or perhaps a place for your chickens to roam free?

Maybe you want a guest room for visiting family, a cozy space to hang out with friends, or a private retreat to escape the hustle and bustle of everyday life. The possibilities are endless!

Step 2: Location, Location, Location

Where you build your pole barn matters. Consider the following:

Sunlight: Do you need lots of natural light for a workshop, or would you prefer shade for a relaxing hangout space?

Access: How easy is it to get to your desired location? Will you need to build a driveway, or is there already one in place?

Utilities: Can you easily connect to electricity, water, and internet? These might seem like obvious considerations, but they'll save you headaches down the road.

Zoning: Check your local building codes and zoning regulations to make sure your dream barn is actually possible.

Step 3: Size Matters

Once you know where you want to build, it's time to figure out how big your pole barn needs to be. This is where things get a little more detailed.

Don't be afraid to go big: Pole barns are typically more affordable than traditional buildings, so don't be afraid to think big. You might be surprised by how much space you actually need.

Think about the future: Even if you don't need all that space right now, it's better to build bigger than you think you'll need. You can always add more features later.

Consider layout: Think about how you want to divide up the space. Do you want a dedicated workshop area, a living space, a storage area, or a combination of all of these?

Step 4: Getting Down to Details

Now that you have a general idea of your layout, it's time to flesh out the details:

Doors and windows: Do you need large garage doors for parking, or would sliding doors be more practical? Consider natural light, ventilation, and security when deciding on windows.

Flooring: What kind of flooring will work best for your intended use? Concrete is durable and affordable, but hardwood or tile might be a better choice for a living space.

Insulation: Will you need insulation for heating and cooling purposes? Proper insulation can significantly improve comfort and energy efficiency.

Finishing touches: Think about lighting, paint, and any additional fixtures that will enhance your pole barn's functionality and style.

Step 5: DIY vs. Hiring Help

Building a pole barn is a great DIY project, but be honest with yourself about your skills and time commitment.

DIY: If you're handy and have the time, building your pole barn yourself can be a rewarding and cost-effective experience.

Hiring help: If you're not comfortable with the construction process, or if you simply don't have the time, there are plenty of contractors who specialize in pole barn construction.

Step 6: Embrace the Flexibility

One of the biggest advantages of a pole barn is its flexibility. You can easily adapt the space to your changing needs.

Remodeling: As your needs change, you can easily remodel and update your pole barn.

Adding features: You can add new doors, windows, or even a loft to create extra space.

Moving it: If you ever need to move your pole barn, it's relatively easy to dismantle and relocate.

Ready to Get Started?

Planning a pole barn project might seem daunting, but it's a rewarding experience. With careful planning and attention to detail, you can create a space that truly meets your needs and reflects your personal style.

Remember, it's your project, so embrace the possibilities and let your imagination run wild! From a cozy getaway to a multi-functional workspace, your pole barn can become the ultimate expression of your dreams.